Introduction

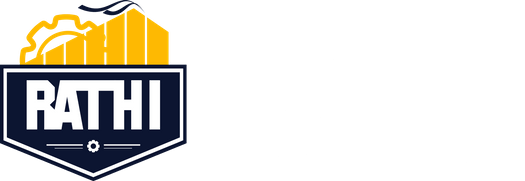

Rubber moulding machines are at the heart of countless industries — from automotive to electrical to medical. But choosing the right rubber moulding machine can be a challenging task, especially with so many types and specifications available. Whether you’re setting up a new production line or upgrading your current setup, making the right choice directly impacts your efficiency, product quality, and cost-effectiveness.

In this blog, we offer expert-backed advice on how to select the right rubber moulding machine for your needs.

Understand Your Application & Product Requirements

Start by defining what kind of rubber parts you’re planning to manufacture:

- Are they solid, hollow, or intricate in design?

- What level of precision and finish is required?

- What type of rubber material are you using?

Understanding your end product helps determine the type of moulding machine — whether compression, injection, or transfer moulding suits best.

Evaluate the Type of Moulding Machine

There are three major types:

- Compression Moulding Machines – Great for low-to-medium volume and simple shapes.

- Injection Moulding Machines – Ideal for high-volume, high-precision components.

- Transfer Moulding Machines – Suitable for complex shapes with embedded parts.

Each has its pros and cons, depending on the production speed, mold design, and part complexity.

Look for High-Speed Hydraulic Systems

Modern rubber moulding machines are equipped with hydraulic systems for faster cycle times, energy efficiency, and consistent clamping pressure. Opt for a machine with:

- High-speed hydraulic response

- Proportional hydraulic control (optional for precision molding)

- Low noise and heat emissions

These features reduce operational costs and increase overall productivity.

Consider Machine Size & Clamping Force

Make sure the machine’s platen size and tonnage match your mold dimensions and pressure requirements. Oversized machines waste energy, while undersized machines lead to poor part quality or tool damage.

Tip: Calculate tonnage based on the projected area of your rubber part and the hardness of the rubber compound.

Prioritize Automation & Control Systems

Choose a machine with:

- PLC or touchscreen HMI controls

- Programmable process parameters

- Data logging for quality control

Automation not only improves consistency but also enables quicker changeovers and better production monitoring.

Focus on Safety & Maintenance

Safety should never be compromised. Look for:

- Emergency stop buttons

- Safety guards/interlocks

- Easy access panels for maintenance

- In-built diagnostics and alarm systems

A well-maintained machine is a reliable machine — easy maintenance features minimize downtime.

Choose a Reliable Manufacturer

A rubber moulding machine is a long-term investment. Work with a manufacturer who offers:

- ISO-certified, durable machines

- Customization support

- Strong after-sales service and spare parts availability

At Rathi Industries, we offer robust, high-performance rubber moulding machines equipped with advanced hydraulic technology and tailored to your application needs.

Conclusion

Choosing the right rubber moulding machine isn’t just about specs — it’s about aligning your machine with your production goals, material properties, and operational scale. By focusing on the key parameters mentioned above, you can make an informed, future-ready investment.

📞 Need Expert Advice on Rubber Moulding Machines?

Talk to our team or Request a Quote today.